Threading a sewing machine and winding its bobbin is a must before getting down to any sewing project. The process of winding the bobbin as well as threading the top part of the machine is quite easy until you get to thread the needle.

Threading a sewing machine and winding its bobbin is a must before getting down to any sewing project. The process of winding the bobbin as well as threading the top part of the machine is quite easy until you get to thread the needle.

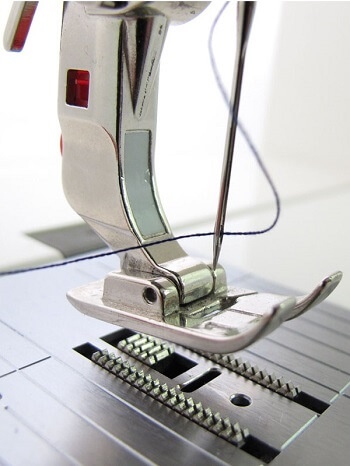

Some high-end sewing machines come with a built-in needle threader, which is quite easy to use and eliminates eye strain, but if you do not have this feature, it must be done manually.

Manual threading can be very frustrating, but with the right procedure, it can be easily done in a few seconds. Below are the steps for manual needle threading.

Put something white behind the needle

This is a tip that applies to both hand sewing needles and sewing machine needles. Placing a white paper, cloth or cardboard material (anything so long as it is white), makes the eye of the needle more visible and therefore easier to thread without straining your eyes.

Experienced sewers usually place white cards on their pin cushions so that it is always ready to assist in the time of need.

Use a thread that matches the eye size

This is a no-brainer. Your thread diameter should match the diameter of the needle eye even before you start pushing it through. Thick threads such as denim or carpet thread should be used with a needle that has a bigger eye as compared to the one used with fine thread.

Forcing thick thread on a tiny eye might work, but you will damage the thread as it is being pulled through when sewing.

Clean cut the thread

For easier penetration, you should cut the thread end cleanly, with no fibers left dangling around. Shredded thread ends usually disperse on touching the needle eye frame, which can be very frustrating due to repeat misses.

Apart from clear-cutting it, the thread end should also be cut at an angle so that you can have a pointy tip that will guide the rest of the thread inside. This tip is mostly visible on thick threads, but as long as you cut it at an angle, it is also there on fine threads despite not being visible.

Stiffen the thread

After cutting it, stiffen the front part of the thread using water, wax, or saliva and roll it between your thumb and index finger. This is especially important if you have a low-quality thread that keeps on unraveling after every try.

A stiffer thread is much easier to push through the needle eye, making the process take a very short amount of time.

Moisturize the other end of the needle

As you are pushing the thread through, apply some water on your thumb and place it on the other end of the needle eye, opposite the thread entrance. This will work as a thread magnet and help direct it through the eye with ease. All that will be left is pulling it through, and the work is done.

Conclusion

Following these steps will certainly simplify the needle threading process as well as the machine threading process at large, enabling you to complete it in a couple of seconds. It might be difficult at first, but after continued practice, as you use your machine, it will become second nature.